END RESULT

With everything operating at max, I got just short of two hours of battery time. Considering my application consists of two 12V batteries wired in series to give me 24V, I am effectively running off one 24V battery.

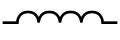

Series battery connection |

I was extremely happy with the time it gave me. Under normal office operating conditions, had I switched one computer off while the power was down and used the other for tasks that are nothing more stressful than spreadsheets, I am quite sure I could get at least double the time out of it, if not more.

It took just on four hours to recharge the batteries. I restarted the PC’s immediately after reverting back to mains so everything was on while the unit was recharging the batteries. I’m not sure if leaving the computers off would have made a big difference to the charge up time.

In conclusion, I would have to say I am extremely happy with my UPS.

I paid R 3,003.00 for it. That included the batteries and the battery housings. In US dollars, at our current exchange rate, that translates to around $411.00

The beauty of this system is if you get an inverter that has the same features as the one I got, you can custom fit it with batteries of your choice and then add as many as you need in parallel depending on what application and backup time you need. With a bit of research and common sense, it should be easy to make your own backup unit with a few lead-acid batteries that can be bought from the local battery retailer.

Parallel battery connection |

PUTTING TOGETHER A UPS OF YOUR OWN

As my unit was already made up for me, I am not going to go through a step by step dialogue on how to make one of these from scratch. Using my unit as a guide, I’m hoping that I am able to provide you with sufficient specifications, diagrams and pictures for you to make your own setup or be able to make an informed decision should you wish to go out and buy one, or have one made.

For this project you will need the following hardware:

- A DC-to-AC inverter, with auto line-to-battery transfer and integrated charging system.

- 12V semi-sealed lead acid batteries or valve regulated lead acid batteries (VLRA) which are completely sealed.

- Polyethylene battery box (This is optional although highly recommended from a safety aspect.)

- AC wiring no less than 18-gauge copper wire and rated for 167°F (75°C) or higher cut to the desired length.

- Battery cables no less than 10-gauge and rated for 167°F (75°C) or higher.

- Metal battery terminals to fit the positive and negative contacts on your particular model of battery.

- Ring cable terminals to secure the battery cables to the DC input connecter on the back of the inverter

I would suggest getting the cables made up at your local auto electrician as it involves the use of specialized crimping tools, which unless you already have in your toolbox, seem to be an unnecessary outlay for the single use you would have for them on this project.

The back of my inverter unit is very clearly marked and shows exactly where to connect the various terminals. The following diagram and close-up of the wiring on my unit should hopefully provide a sufficient guide.

To the left, are the terminals for the DC input(battery terminals). This would take the 10-gauge wire that runs from the positive and negative terminals of the batteries. It is advisable to keep the length of these cables as short as possible. Using cables that are too small in diameter or too long will cause a resistance buildup and could stress the inverter, resulting in lower efficiency, lower peak output power, and reduced surge power. At worst, the cable could generate sufficient heat to start a fire.

Place the correct polarity battery ring terminal over the battery terminal plate at the rear of the unit. This should be marked with a + or – It may also be coloured red or blue. Do not place any additional items like washers or nuts between the terminal plate and the cable ring as overheating may occur. The terminal stud (screw) is not designed to carry current. Make sure to tighten the cable ring to the terminal plate with the appropriate nut to ensure maximum connectivity.

Next up is the AC input supply. My unit provides a three station terminal block to connect the wires from the AC inlet (wall socket plug) to the inverter. The positioning for the wires have been clearly marked as HOT (positive) NEUTRAL (negative) and GROUND (earth). You would need to check the wiring colour code for your country or region before attempting to connect the wires to the terminal block. As mentioned, a minimum of an 18-gauge cable should be used. Most general purpose three core extension wires would suffice. The length of this cable is not as crucial as the cabling to the battery terminals and may be cut to a length that suits your application.

To the right of the unit is the output socket. This may take on various configurations depending on the appliance standard for your country or region. The cable that came with my unit ended with a single kettle plug connection, which was useless for my application, so I cut it off and replaced it with a multi-plug adapter. If you can find an extension lead that fits the inverters outlet and has sufficient sockets to meet your requirements, you may not have to adapt it like I did.

That is effectively all there is to putting your own UPS together. Depending on your needs and budget, you could build a UPS that provides monstrous battery capacity. Your only limitations would be weight, the need for portability, and sufficient ventilation.

There is presently no short-term solution for the electricity supply problem in South Africa.

Without spending a small fortune, the Inverex 1000 with deep discharge lead-acid batteries is the best solution for me. During the day, we can keep the office going without any downtime. In the evening, we can have fun and never get stuck sitting in the dark with nothing to do.